Neilsoft Campus in Pune [Image courtesy of Neilsoft]

Neilsoft campus - connecting people, technology and nature

Neilsoft Campus is a vast three-acre office complex in Pune, India. It is designed to house a variety of engineering design, software development, and research activities, making it a centre of innovation. At the core of this site is a 10-story commercial office structure that has been meticulously designed to meet different corporate needs and operational efficiencies. Neilsoft recognized that there was scope for improvement in making the building operations more effective by using technology. This flagship project exemplifies Neilsoft's dedication to combining emerging technology and sustainable design concepts in the Architecture, Engineering, and Construction (AECO) business. Neilsoft identified opportunities to enhance energy efficiency, maintenance optimisation and resource allocation with the availability of emerging technologies, Neilsoft launched a project to further modernise facility management using digital twin technology.

Digital twin technology to the rescue

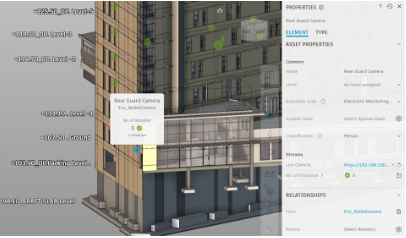

Neilsoft building digital twin [Image courtesy of Neilsoft]

Digital Twin (DT) technology creates an accurate digital picture of physical assets in use, dramatically improving building and plant management and efficiency. By integrating these digital models with Internet of Things (IoT) data, organisations get real-time data visualisation, simulations, and intelligent decision-making across the asset lifespan. By evaluating sensor data, DT technology offers predictive maintenance, minimising downtime and increasing operational efficiency.

Neilsoft leveraged its BIM, BMS & Digital Technologies skills and embarked on this project to integrate digital twin technology using Autodesk Tandem and Autodesk Construction Cloud (ACC). The primary aim was to develop a full digital picture of the entire campus, allowing for real-time monitoring, predictive analytics, and increased asset management capabilities. This strategy aims to increase operational openness while simultaneously driving considerable efficiency gains across the institution.

A systematic step-wise approach to success

- Goal Alignment: Mapping integration strategies for Building Information Modelling (BIM) data and sensor deployment aligned with Neilsoft’s business goals, focusing on energy efficiency and operational transparency.

- Stakeholder Engagement: Collaborating with stakeholders to understand operational needs and challenges, ensuring a holistic approach to implementation.

Step 2: Digital twin creation: Building a comprehensive virtual model

Neilsoft building digital twin implementation process

[Image courtesy of Neilsoft]

- BIM Data Integration: Using Autodesk Tandem to integrate detailed architectural and Mechanical, Electrical, and Plumbing (MEP) models, forming a precise virtual representation of the campus.

- Sensor Data Incorporation: Integrating IoT sensors for real-time data on energy usage, environmental conditions, and asset performance.

Step 3: Sensor deployment: Installing the nerve

- Strategic Sensor Placement: Installing sensors strategically across critical systems like Heating, Ventilation, and Air Conditioning (HVAC) and lighting for comprehensive data collection.

- High-Quality Sensors: Utilising durable and accurate sensors to ensure reliable data flow into the digital twin.

Step 4: System testing and calibration: ensuring precision

- Thorough Testing: Calibrating the digital twin through rigorous testing to validate real-time accuracy and performance.

- Accuracy Verification: Cross-verifying sensor data with manual measurements to ensure data reliability.

Step 5: Training and rollout: Empowering the operations team

- Comprehensive Training: Providing hands-on training on Autodesk Tandem and ACC for effective use in daily operations.

- User Adoption: Supporting teams to ensure smooth transition and adoption of new technology.

Step 6: Ongoing evaluation: Continuous improvement

- Routine Assessment: Establishing a routine for evaluating system performance and user feedback.

- Technology Upgrades: Planning for future enhancements to keep the digital twin at the forefront of innovation.

The technology showrunners: Autodesk Tandem and Autodesk Construction Cloud

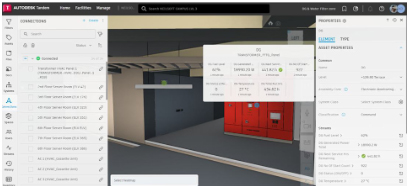

Neilsoft building in Tandem [Image courtesy of Neilsoft]

Autodesk Tandem and Autodesk Construction Cloud were instrumental in the digital twin implementation at Neilsoft Campus. Autodesk Tandem provided a platform for integrating BIM data and IoT sensor data, creating a dynamic digital twin environment. This allowed for real-time visualisation of building operations, predictive maintenance insights, and energy performance analytics. Autodesk Construction Cloud facilitated seamless collaboration among project stakeholders, ensuring efficient data management and workflow integration.

Autodesk Tandem enabled:

- Digital Twin Input: The integration of BIM data [Autodesk Revit and Industry Foundation Classes (IFC) models] to achieve accurate virtual representation.

- Inventory Management: Streamlined facility operations management by grouping and tracking assets.

- Streaming and IoT Integration: Realtime data visualisation through seamless integration with IoT sensors.

- Predictive Analytics: Historical data helped create predictive, preventive, and prescriptive maintenance models.

- Connections: Workflows were enabled with notifications and approvals, increasing operational agility.

- Integration with Autodesk Construction Cloud: Improved collaboration via capabilities such as Autodesk Docs for document management.

Benefits reaped after a successful implementation

- Energy Efficiency: Within Autodesk Tandem, a sophisticated notification system was implemented to continuously monitor the usage of each component. This proactive method provided accurate insights into energy use trends and proposed practical adjustments, resulting in significant gains in total energy efficiency across the Neilsoft Campus.

- Improved Maintenance: Neilsoft improved maintenance by including preventive maintenance capabilities, which significantly reduced downtime and cut maintenance costs. This preventive maintenance strategy not only extended the operating life of vital assets but also maximized their performance, assuring smooth and uninterrupted campus operations.

Benefits realised by Neilsoft from digital twin

[Image courtesy of Neilsoft]

All with a constant focus on sustainability

To ensure the Neilsoft Campus project's success, a comprehensive approach was taken to design a three-acre sustainable, energy-efficient office complex. The design included a variety of green efforts, such as water conservation and management, rainwater gathering, and water recycling for landscaping. Solid waste management systems were also put in place, along with energy modelling and assessments, to maximise resource utilisation.

The campus has electric vehicle charging stations, solar power generation, and innovative material sourcing tactics to reduce construction time and costs through reuse and recycling. The project sought to achieve up to 20% higher energy efficiency and cost reductions than comparable office campuses. Neilsoft addressed these objectives with thorough design and engineering, resulting in up to 15% cost decrease while maintaining high quality standards. This complete sustainability approach not only improves operating efficiency but also demonstrates Neilsoft's dedication to environmental responsibility in the AEC sector.

Follow us on Facebook

Follow us on Facebook Follow us on Twitter

Follow us on Twitter Watch us on YouTube

Watch us on YouTube Join us on Linkedin

Join us on Linkedin Follow us on Pinterest

Follow us on Pinterest